Sakai Forged Blades are undeniably Sakai’s most famous traditional craft.

When you walk the streets of Sakai, you can hear the sound of hammers pounding hot blades and the metallic scraping noise of knives being sharpened. Sakai’s history to iron and steel dates back to the Kofun period (2s50-538 CE) when groups of skilled artisans were gathered in Sakai to forge iron tools needed to construct Kofun. Over time, the craft took on different shapes and the forged blades Sakai boasts to the world today were built upon its devotion to the advancement of techniques required to manufacture the craft.

You can take a closer look at the secret behind the technology of matchlock guns at the permanent exhibit at the Sakai City Museum

Sakai’s Prosperity Through Gun Production

When matchlock guns arrived in Tanegashima Island during the Sengoku period (1467-1615 CE), it took no time for the new blacksmithing techniques to reach Sakai, then the center of trade and exchanges for surrounding regions. Aided by its accessibility to saltpeter (potassium nitrate), an ingredient used in making gunpowder, manufacturing of matchlock guns began in Sakai where there already was a foundation for smithery. But manufacturing guns required techniques that did not yet exist in Japan at the time and, even for the group of blacksmiths skilled in forging iron, creating a perfectly cylindrical gun barrel and using screws as the breech plug involved unfamiliar techniques that had to be mastered anew. It was through repeated cycles of trial and error that the production of matchlock guns that fire bullets in a straight line was successfully achieved.

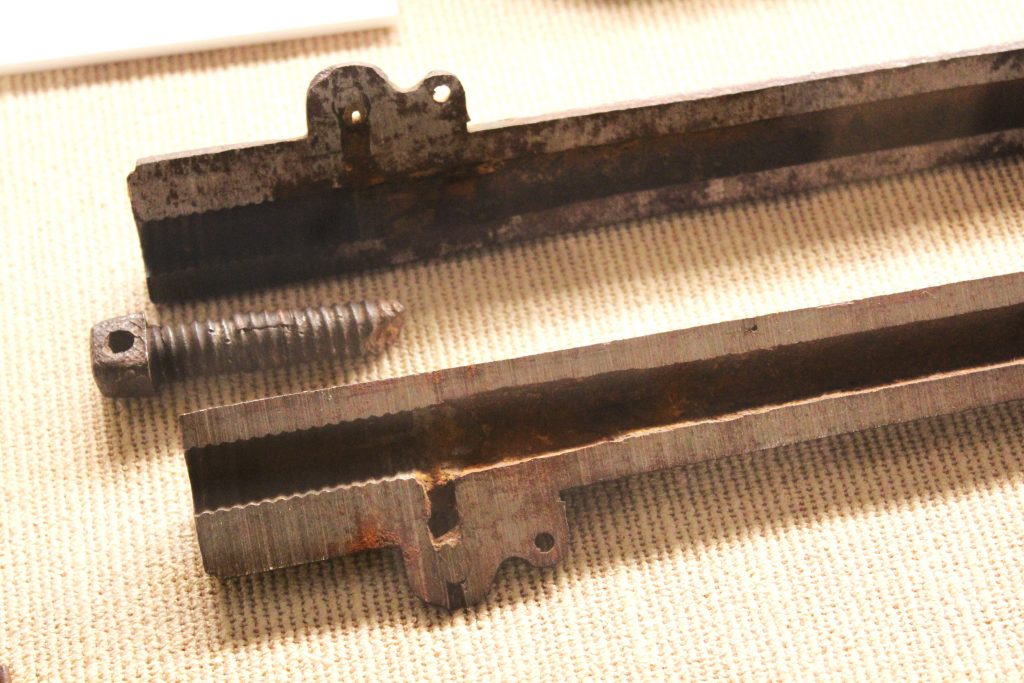

The interior of the barrel, stored at the Sakai City Museum

The popularization of matchlock guns brought changes to warfare and fortification and greatly impacted the history of Japan. According to some records from the Edo period (1600-1868 CE), the price of one gun was equivalent to the price of rice consumed by one individual over two years. It is not an overstatement to say the City of Sakai prospered due to its gun production. In order to ensure efficiency in mass gun production, a division of labor was introduced into the process.

Matchlock guns of various sizes are on exhibit at the Sakai City Museum

From Production to Maintenance

It is believed matchlock guns first came to Japan through Tanegashima Island. Much like its English counterpart, the Japanese word for matchlock guns, hinawaju (literally “fuse gun”), originates in the match cord used to ignite the gunpowder to fire the gun. Matchlock guns did not largely advance because of their structural characteristics. In addition, they could not be fired continuously, and it took 20 to 30 seconds even for a trained shooter due to the numerous steps were required before firing.

The procedure for firing a matchlock gun

1.Light the match cord. *Match cord is treated with gunpower and easily lit.

2.Put the gunpowder and the bullet into the mouth of the barrel using a ramrod.

3.Put the primer in the flash pan and close the pan cover.

4.Attach the match cord to metal tongs.

5.Open the pan cover and aim.

6.Pull the trigger and shoot.

When the trigger is pulled, the match cord is pushed onto the flash pan containing the primer and the primer ignites, which in turn ignites the gunpowder in the barrel. The explosion of the gunpower discharges the bullet. Saltpeter used as an ingredient for making bullets was easily obtainable in Sakai and, it is believed, was sold with the guns as a set alongside maintenance and repair services that were also available.

The Sakai City Museum

Located inside Daisen Park which is situated in the center of a UNESCO World Heritage Site, Mozu-Furuichi Kofun Group (Mounded Tombs of Ancient Japan), the Sakai City Museum houses exhibits on the rich history and culture of Sakai City. In addition to its wide range of permanent exhibits that include Kofun , hinawaju, blades production, and traditional performing arts, special exhibitions and temporary exhibitions are held several times a year. During the Edo period, many gunsmiths lived in the area along the seashore in Sakai where gun firing ranges were located. Today, the area is called Teppocho, which literally means “gun town”. The history of the area is commemorated with a monument in front of Nankai Railway’s Shichido Station where a firing range once stood.

During the Edo period, many gunsmiths lived in the area along the seashore in Sakai where gun firing ranges were located. Today, the area is called Teppocho, which literally means “gun town”. The history of the area is commemorated with a monument in front of Nankai Railway’s Shichido Station where a firing range once stood.

“Monument dedicated to the history of Sakai guns, and the site of firing range” (Designated as a Tangible Cultural Property of Sakai City)

Sakai and Tokugawa Ieyasu, Japan’s Greatest Shōgun

During the Siege of Osaka—a series of battles between the Tokugawa shogunate and the Toyotomi clan that took place between 1614 and 1615—the then shogun Tokugawa Ieyasu ordered the gunsmiths in Sakai and Kunitomo (Nagahama City in Shiga Prefecture today) to create the Keicho Great Matchlock Gun that has now been designated as a Tangible Cultural Property of Osaka Prefecture.

Among the numerous firearms that were used during the Summer Campaign of the Siege of Osaka (1615 CE), none has a stature equal to this mighty matchlock gun which is 3 meters in length and weighs 135 kilograms. In addition to its impressive size, the beauty of this gun as a work of art, represented in its metal inlays for instance, is extraordinary.

When Tokugawa Ieyasu ordered the gunsmiths around the nation to create a cannon in 1609, no one came forward to take on the task until Shibatsuji Riemon, a gunsmith from Sakai, did. Riemon then spent some two years and brought to life a 3.25-meter-long giant artillery.

The great cannon is currently owned by Yasukuni Jinja Shrine in Tokyo and a replica has been created and is on exhibit at the Sakai City Museum

A Special Seal of Authenticity, ”Sakai-Kiwame”

As the demand for battle-ready guns diminished when a stable government brought about the peaceful Edo period following the war-torn Muromachi period (1336-1573 CE), use of guns in gunnery and hunting became more prevalent. Guns became more of an art piece than a practical tool and ornamental guns became trendy and even a sort of status symbol.

It was around this time that tobacco was introduced to Japan and grew in popularity. Many highly skilled gunsmiths who had been producing swords in addition to guns found an opportunity and began to produce tobacco knives that were used to chop tobacco leaves. The knowledge of knife manufacturing expanded with this shift, eventually resulting in the production of first-rate knives in Sakai. The superior sharpness of the tobacco knives made in Sakai were recognized by the Tokugawa shogunate by way of allowing a special seal of approval, “Sakai-Kiwame”, which authenticates the ultimate quality of Sakai knives. This prestige led to wide recognition and a high reputation across the country followed shortly after.

Every step of the manufacturing process is done manually by master artisans

Knives of various types

Preserving the Natural Umami of Foods

Sakai blades are hammer-forged knives that are produced with a particular forging technique in which soft iron and steel are heated at a high temperature then hammered down to thin and shape the metal. Hammering is everything, according to some artisans, as the work of hammering determines the sharpness and durability of the end product.

The process of heating and hammering is repeated

A crucial process to ensure the quality of knives

Single edge blades are the standard for hammer-forged knives. The edge of a well sharpened knife, although it looks smooth to a naked eye, actually has a jagged edge, with micro—2/1000 millimeter—serrations, that bites into the surface and cuts food ingredients. The sharper the edge is, the less damage the cut causes to the texture of the ingredient, and the clean, swift cut creates a beautiful cut plane and protects the natural flavor of the ingredients. One can say it is a technology born out of the quest for the best food in its best state, a quest conceivable only in a place like Osaka, the Nation’s Kitchen, a culinary center of Japan.

Knives Last Generations with Proper Maintenance

Even the sharpest knives are prone to damage as the jagged edge becomes dull with use. Knives are, perhaps unexpectedly, a delicate tool despite its possible use as a lethal weapon. Once a knife becomes dull, the edge of the knife is straight and the knife can slip and slide over the ingredients, making it difficult to cut. By sharpening the knife—by grinding and shaving off the dull edge—the dull knife can be saved. With regular maintenance, a knife lasts as long as it maintains its edge. In fact, a knife is used across generations more often than not, passed down from parents to children and even from grandparents.

Rough polishing on sharpening wheels requires diligently checking the condition of the blade

Checking for any distortion

Just as the work to produce guns was divided long ago, the manufacturing process of the knives today is divided into three specialized processes: forging, sharpening, and handle attaching. Through the partnership of professionals, each with their own specialized skills, their craft is further enhanced and high-quality knives that command the attention of chefs worldwide are produced.

It is said more than 90% of professional chefs in Japan regularly use Sakai knives. Even the knives found in the kitchens of personal homes may have been made in Sakai as a result of collaboration with other manufacturers to produce OEM knives. The mastery of these Sakai knives is a product made possible only with the foundation laid by preceding industries of sword- and gun-manufacturing.

The Sakai Traditional Crafts Museum

The Sakai Traditional Crafts Museum showcases and sells a collection of Sakai’s traditional crafts and craftsmanship. Hands-on workshops in which the craftsmanship can be experienced firsthand are also offered. Get a knife or scissors sharpened and learn about the history and production of Sakai knives at the adjacent Sakai Knife Museum CUT.

A Deeper Look at Gun Productions Old Gunsmith Workshop and Residence

The Inoue Sekiemon’s Residence, a gunsmith’s home designated as a Sakai City Tangible Cultural Property opens as a museum with public access in March 2024! Located in the northern part of the area where many gunsmiths once lived, the Old Gunsmith Workshop and Residence is Japan’s last and only remaining gunsmith workshop and residence from the Edo period. Invaluable historical documents concerning gun productions have been located at the site including over 20,000 pieces of ancient manuscripts.